Requirement Consumption Review

Assuring Supplier Readiness for New Product Introductions and Transfers

The Requirement Consumption Review (RCR) is SQA’s structured, early-involvement service that ensures your suppliers are fully capable and ready to execute new product introductions, product transfers, and engineering changes. Through a collaborative, cross-functional review, SQA helps confirm that the supplier has thoroughly consumed and understood every requirement — from the purchase order and engineering definition to quality and capacity expectations.

This proactive approach identifies and mitigates risks before production begins, supporting on-time launches and right-first-time manufacturing.

Collaborative, pre-production, single-day review conducted by a cross-functional team focused on part-specific manufacturing capability. A report is generated using a tailored checklist that identifies Client and Supplier actions. SQA shares these actions with the supplier and checks in to monitor their completion.

RCRs are designed for:

- New suppliers or complex programs

- Product or service transfers between sites

- High-risk or highly regulated commodities

- Parts with critical quality or performance requirements

The review focuses on supplier preparedness to meet contractual, technical, and quality obligations. It builds strong communication between clients, suppliers, and SQA’s experts, establishing alignment early in the product lifecycle.

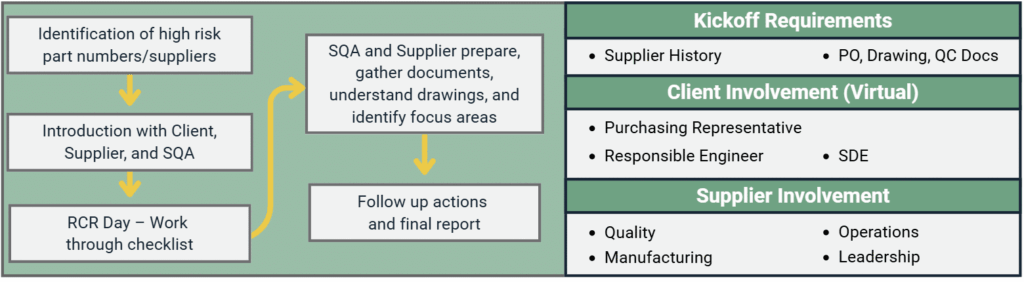

- Risk Identification: Determine high-risk part numbers or suppliers requiring evaluation.

- Preparation: SQA and the supplier gather purchase documents, drawings, and key quality records.

- RCR Day (Virtual or On-Site): Cross-functional workshop with Client, Supplier, and SQA team to work through the tailored RCR checklist.

- Report & Follow-Up: SQA delivers a detailed report outlining supplier strengths, gaps, and required actions, followed by periodic check-ins to verify completion.

Each RCR examines supplier performance and readiness in the following areas:

- Contract Review: Verification of all contractual and technical requirements.

- Product Design & Definition: Understanding of key part features and specifications.

- Build Plan: Review of manufacturing processes, flow, and capacity.

- Inspection & Test: Evaluation of inspection methods, equipment, and calibration.

- Corrective & Preventive Actions (CAPA): Assessment of issue resolution mechanisms.

- General Workmanship: Review of cleanliness, handling, and product protection practices.

- Property & Tooling Management: Evaluation of control, storage, and maintenance systems.

SQA partners with leading organizations in quality-critical industries to deliver robust RCR assessments that safeguard compliance, quality, and patient trust.

Other value outcomes include:

- Reduces manufacturing and supply risk.

- Improves first-pass yield and launch success.

- Prevents costly late-stage design or manufacturability changes.

- Ensures readiness for PPAP and production ramp-up.

- Strengthens client–supplier collaboration and accountability.

SQA delivers RCR managed services globally, leveraging our network of technical experts and quality professionals across all major manufacturing regions. Whether your project involves an emerging supplier or a critical transfer, SQA ensures capability and compliance from day one.

Contact us today to learn more.