Aerospace and defense supply chains are entering an extended period of high-rate production – meaning suppliers are being asked to ramp up faster, deliver more consistently, and meet quality requirements with little margin for error. Yet many suppliers are being pushed to performance levels they have never operated at before.

Aerospace and defense supply chains are entering an extended period of high-rate production – meaning suppliers are being asked to ramp up faster, deliver more consistently, and meet quality requirements with little margin for error. Yet many suppliers are being pushed to performance levels they have never operated at before.

When gaps emerge – whether due to equipment limitations, documentation inaccuracies, inexperienced personnel, or accelerated production schedules – OEMs feel the impact immediately. Late deliveries, nonconformances, and inconsistent throughput can quickly threaten program milestones and erode downstream confidence.

SQA Services supports OEMs and Tier-1s in navigating these challenges through structured supplier capability assessment and development programs designed specifically for regulated aerospace environments.

Understanding Capability Assessment in Aerospace & Defense

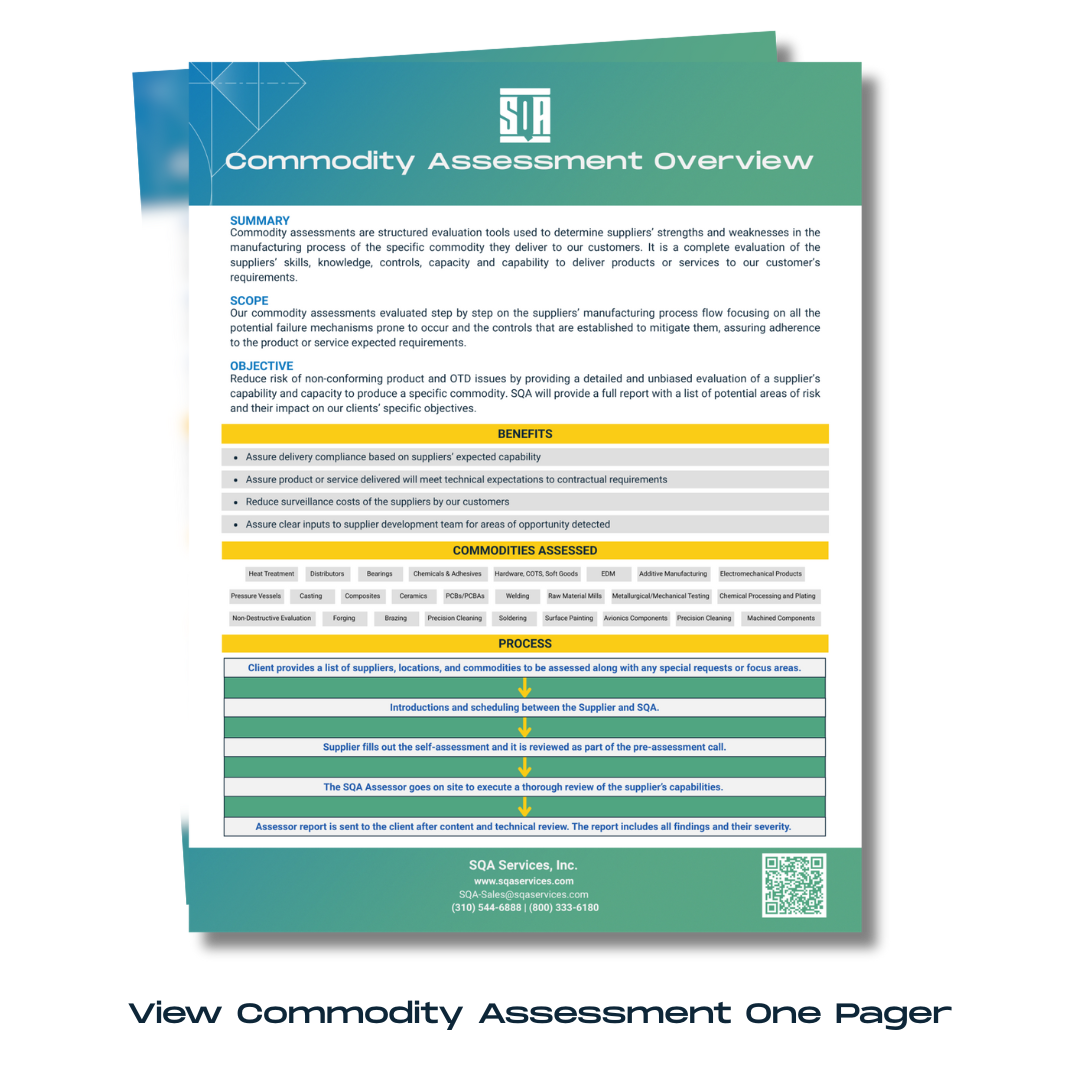

A capability assessment is the foundation for improving supplier performance. Organizations cannot stabilize production or launch recovery efforts without first developing a clear, data-driven understanding of a supplier’s true readiness.

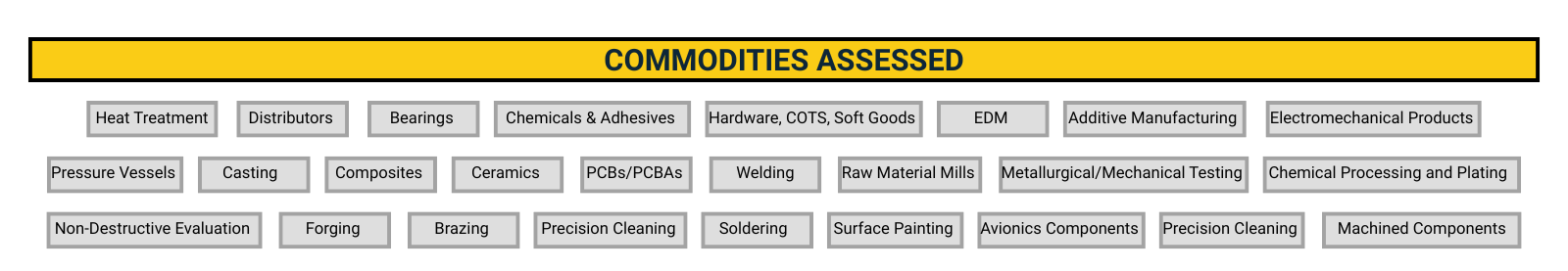

SQA’s assessment methodology is built around six core pillars:

- People: Experience levels, training maturity, workforce stability

- Process: Process flow, controls, discipline, and repeatability

- Tooling & Equipment: Capacity, maintenance practices, calibration, constraints

- Documentation: Work instructions, travelers, inspection criteria, and configuration control

- Throughput: Cycle times, flow barriers, and production bottlenecks

- Quality Performance: Historical trends, escape types, yields, and corrective-action maturity

This structured capability assessment framework mirrors the approach SQA uses across its Supplier Assessments solution – where commodity-specific, engineering-aligned evaluations determine whether a supplier is ready to meet contract requirements.

By establishing traceable, documented baselines, SQA helps OEMs eliminate guesswork, identify root-cause drivers of instability, and prioritize the most impactful interventions.

From Assessment to Recovery: A Proven Path to Stability

Once the capability assessment is complete, SQA develops a tailored recovery roadmap that includes:

- Production stabilization and resource alignment

- Training and competency development for supplier personnel

- Parallel-path remediation to fix quality and documentation gaps

- Manufacturing readiness checkpoints aligned to OEM expectations

- Process control enhancements to support long-term repeatability

This model has helped aerospace suppliers move from 60% yield performance to 90%+ in just weeks, restoring flow, protecting delivery schedules, and rebuilding trust with OEMs.

These results align with SQA’s broader assessment philosophy: measurable, actionable improvement driven by objective data and on-site technical expertise.

Why Capability Assessments Matter Now More Than Ever

As aerospace and defense enter a sustained period of high-rate production, suppliers must demonstrate readiness long before parts reach first article inspection or full-rate manufacturing. OEMs are increasingly demanding:

- Greater transparency

- Stronger process control

- Documented readiness checkpoints

- Validation before production commitments

A proactive capability assessment ensures suppliers can meet these expectations and protect program timelines. It also reduces schedule volatility, mitigates risk, and builds stronger long-term supplier partnerships.

SQA’s supplier development framework equips OEMs and Tier-1s with a proven, scalable model – one that helps them quickly identify gaps, accelerate recovery, and elevate suppliers to the performance levels modern aerospace production requires.

Strengthen Your Supplier Base with a Capability Assessment

To learn how SQA can support your capability assessment, supplier recovery, and readiness programs, contact us today.