Aerospace escapes cost far more than rework – they create schedule disruption, safety concerns, customer dissatisfaction, and cascading delays throughout the aerospace supply chain. Yet most escapes originate from predictable causes: documentation inaccuracies, process drift, latent training gaps, and accelerated production environments. This is why strengthening source inspection processes has become essential for preventing issues before parts ever reach final assembly.

Why Source Inspection Matters in Modern Aerospace Supply Chain

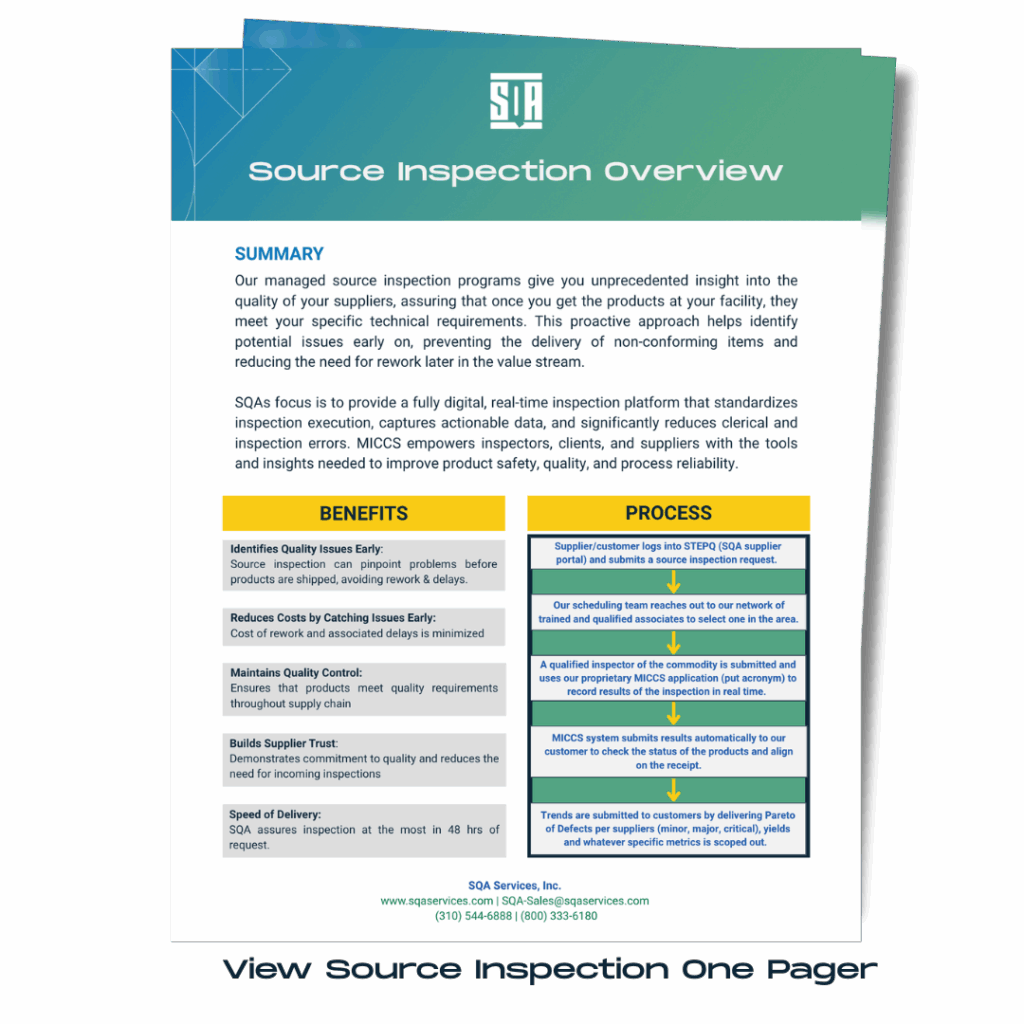

Independent Source Inspection, when paired with risk-based planning, is one of the most effective ways to prevent escapes before parts reach final assembly.

SQA’s inspection model brings technical rigor, trained inspectors, and inspection plans aligned to engineering requirements. The differentiator is the data-driven approach behind the service. By analyzing defect history, nonconformance trends, documentation issues, and supplier performance, SQA adjusts inspection depth and frequency based on actual risk- not assumptions.

The Results: Lower Escape Rates and Higher Supplier Maturity

Programs that adopt this model consistently achieve less than one percent (1%) rolling escape rates, reinforcing that disciplined oversight at the supplier source works.

In a market where Original Equipment Manufacturers expect suppliers to deliver right-first-time quality with minimal oversight, independent source inspection offers a scalable, cost-effective safeguard that protects production schedules and improves supplier maturity.

Strengthen Your Supplier Oversight with SQA

SQA Services helps aerospace organizations reduce escapes, stabilize supplier quality, and implement risk-based Source Inspection programs that deliver measurable impact. Contact us today!